At last I'm going to test board but I'm not quite sure it will work or not.

So,I decide to test it with LED first.I have a test board like below and use four small hold together at negative pole and at positive pole I pull it up with +5 vDC to limit the current.It's simple test circuit.

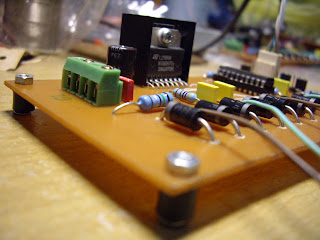

Then I connect all wire like below.It quite look mess.I use my simple rectifiier +5vDC and +12vDC to be the power source feed to my board.I've to aware and make sure for the 5v and 12v.Not to swap it.

It work !!! I'm so glad.

Let see video in below. The light from four LED can blink.

Seem there's a little problem for the green LED that not blink.So,I decide to change it to be the same colour.

Look good and seem to be ok for my step motor.The real use.

Yahoo, My step motor can be rotated according to my control.I take time to find the pattern from LED.

After try out and find the information from Mr.Google again and again.

Finally,I finish my board.

See the video for the rotation of my step motor from controlling of my board.

Next time will be hardware part which I've no experience before to build CNC machine.

Let see how if I can do it ugly or not ....